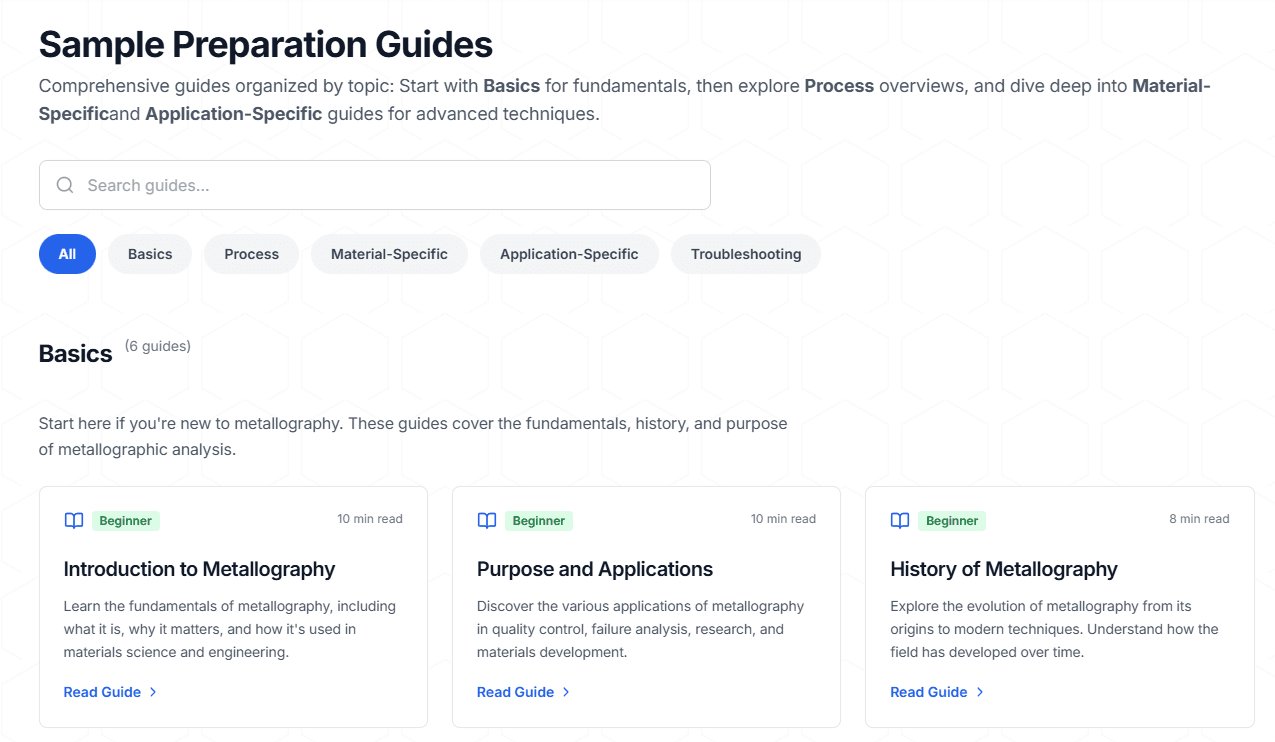

What is Metallography?

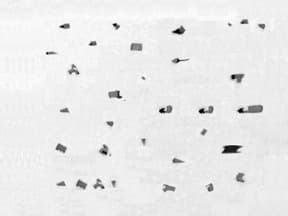

Metallography is the scientific study and analysis of the microstructure of metals, alloys, ceramics, and composite materials. Through systematic sample preparation and microscopic examination, it reveals grain boundaries, phases, inclusions, and defects that determine material properties.

Essential for quality control, failure analysis, and materials research across aerospace, automotive, medical devices, energy, and additive manufacturing industries.

The Five-Step Preparation Process

Sectioning

Cut sample to size with minimal damage

Mounting

Embed in resin for handling

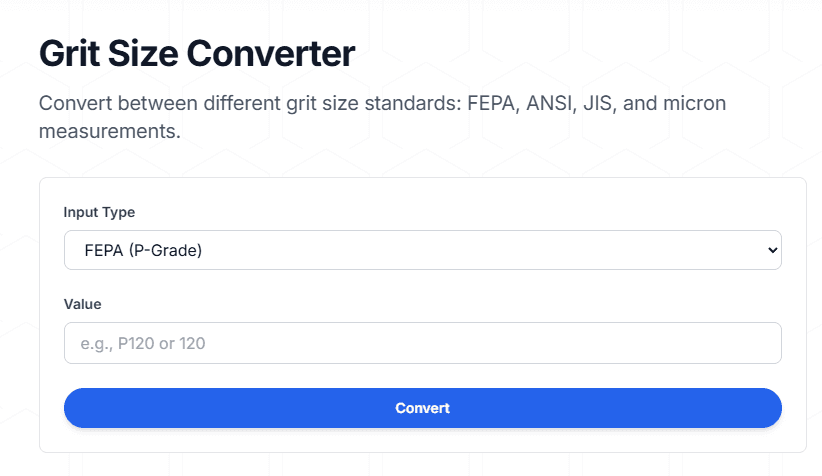

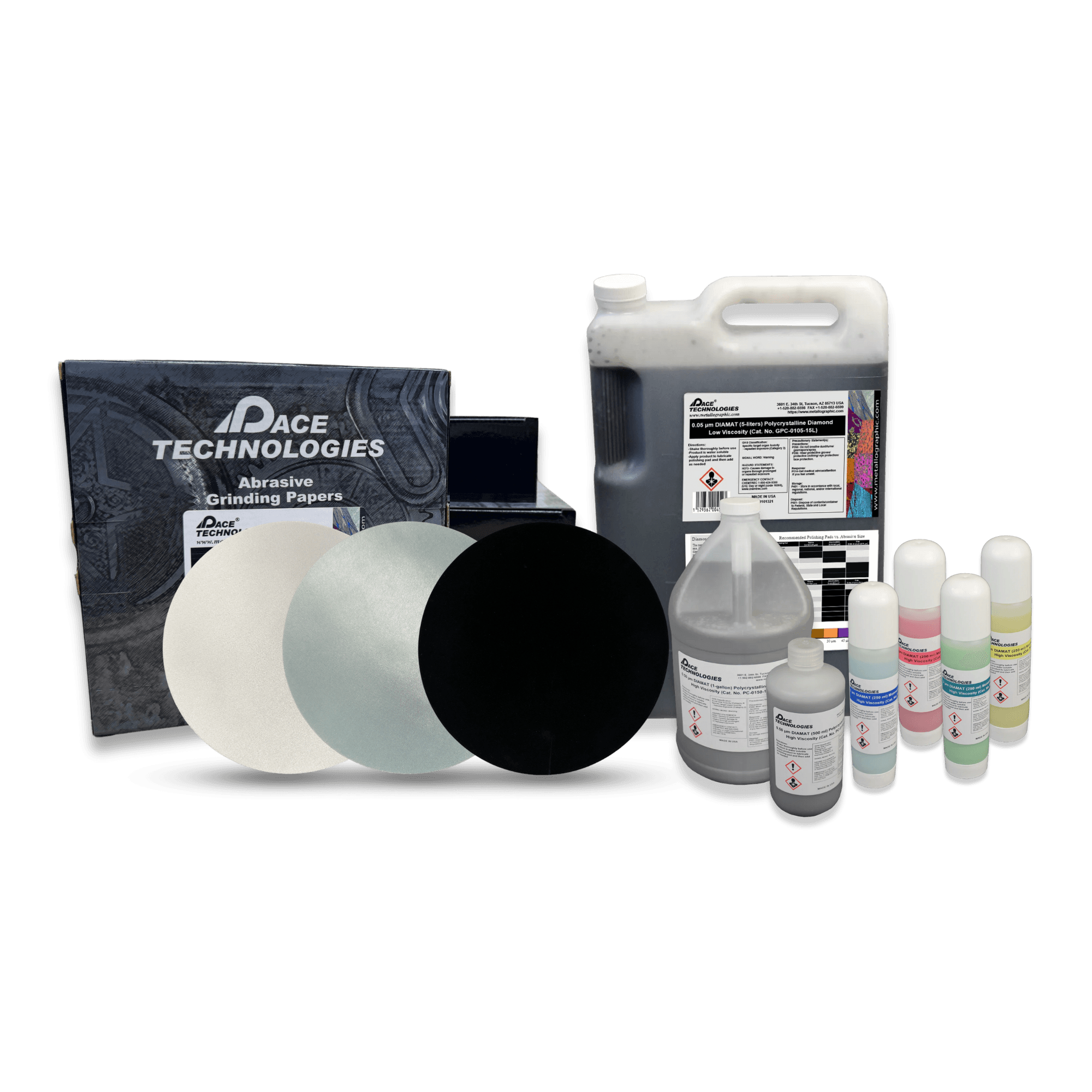

Grinding

Remove damage with progressive abrasives

Polishing

Achieve scratch-free mirror surface

Etching

Reveal microstructure with reagents

Explore our preparation guides, reference tools, ASTM and ISO standards, and reference materials for detailed procedures.