Vibratory Polishing: When It Outperforms Advanced Final Polishing Methods

Introduction

In metallography, the final polishing stage determines whether true microstructural detail is revealed or obscured by deformation, scratches, or relief. While advanced mechanical polishing methods—such as chemomechanical polishing, automated force-controlled systems, and short-duration colloidal silica polishing—are capable of excellent results, they do not always achieve the ultra-flat, deformation-free surfaces required for the most demanding analyses.

Vibratory polishing occupies a unique position in metallographic preparation. Unlike conventional mechanical polishing, it removes material extremely gently through low-amplitude oscillation, enabling the highest-quality surface finishes with minimal deformation. This makes vibratory polishing the preferred technique in specific scenarios where traditional methods may fall short.

This article outlines when and why metallographers should choose vibratory polishing, its advantages over other advanced polishing techniques, and how to optimize the process for the best possible surface finish.

What Makes Vibratory Polishing Different?

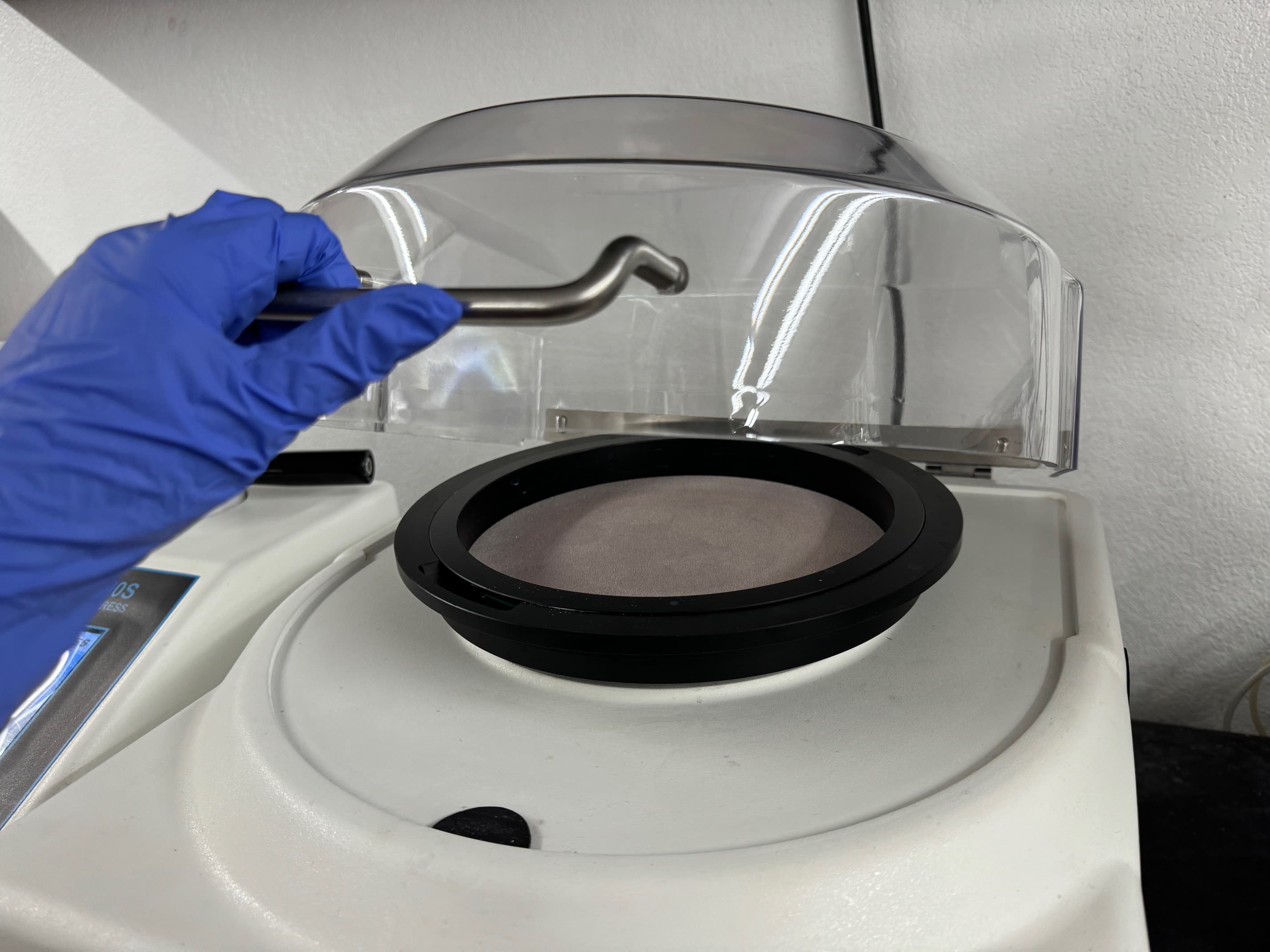

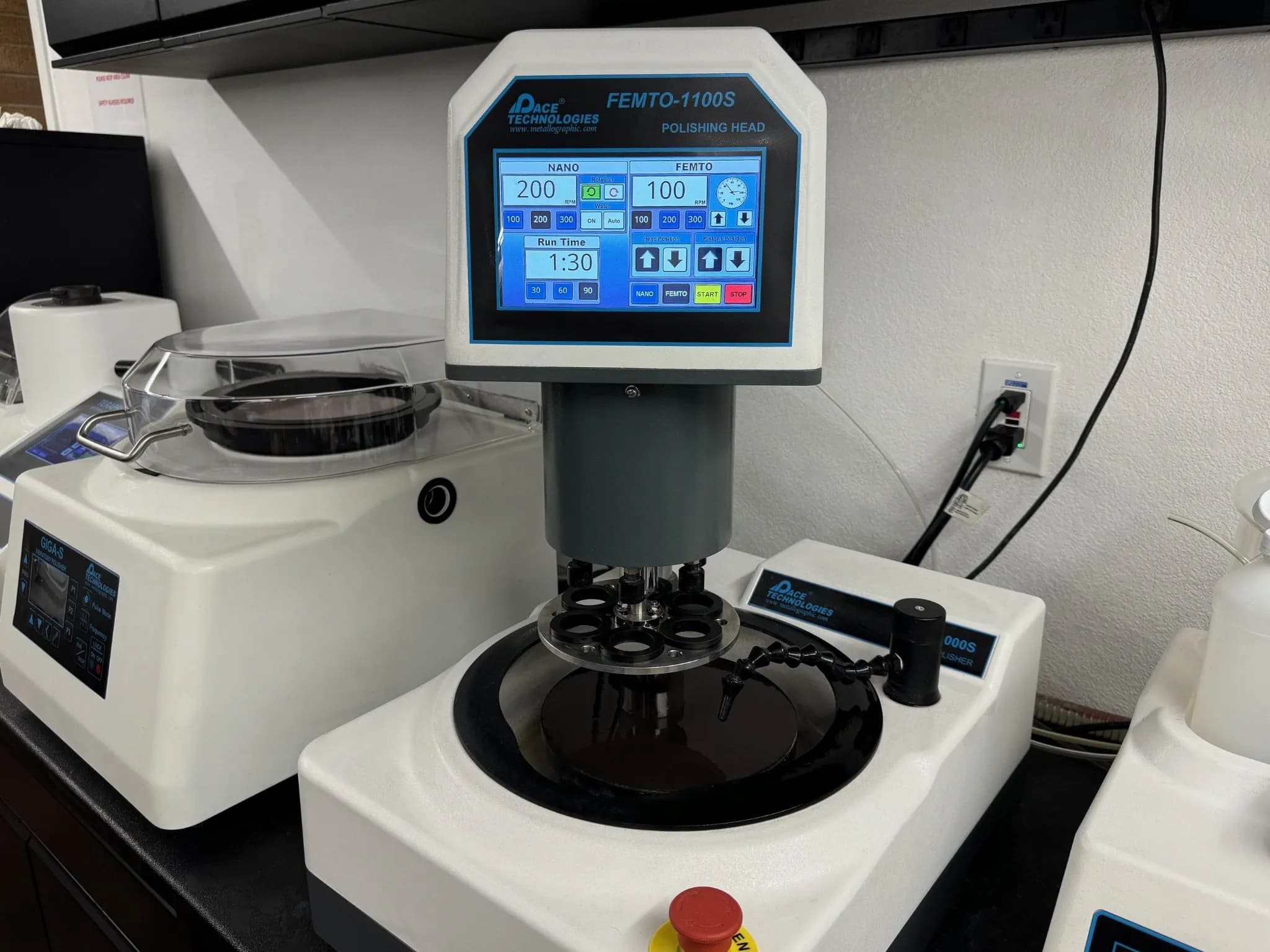

Vibratory polishing uses a horizontal, low-frequency vibration—typically 1200–2000 cycles per minute—combined with a polishing slurry to produce material removal far gentler than traditional polishing. Instead of rotating platens and applied load, the abrasive slurry does nearly all of the work, allowing the surface to equilibrate and naturally reduce relief.

Key characteristics include:

- Nearly load-free material removal – prevents deformation, rounding, and grain pullout.

- Exceptional flatness – ideal for specimens requiring precise height uniformity.

- Longer cycle times – often 30 minutes to several hours depending on the material and surface requirements.

- Minimal operator intervention – consistent, repeatable results once process parameters are established.

When to Choose Vibratory Polishing Over Other Final Polishing Techniques

While vibratory polishing is not necessary for every metallographic application, there are crucial scenarios where it provides superior results.

1. When Surface Finish Quality Is Paramount

For high-resolution imaging techniques—such as electron backscatter diffraction (EBSD), transmission electron microscopy (TEM) preparation, and high-magnification SEM—any surface deformation will compromise data integrity. Vibratory polishing minimizes smearing and deformation to levels unmatched by standard mechanical polishing.

Ideal for:

- EBSD on steels, nickel alloys, aluminum, and titanium

- Surface-sensitive SEM imaging

- Superalloys containing soft and hard phases

- Materials prone to strain-induced transformation

2. When the Material Contains Hard/Soft Phase Combinations

Materials like cast irons, nickel-based superalloys, metal matrix composites, and many multiphase alloys experience relief during mechanical polishing due to differential wear rates. Vibratory polishing allows these phases to “settle” into a uniform plane without aggressive abrasion.

Benefits include:

- No exaggeration of microstructural relief

- Improved boundary delineation

- Better preparation for etching and imaging

3. When Scratch Removal from Previous Steps Is Difficult

Some materials, such as tool steels, tungsten carbides, ceramics, or very soft metals like copper, are prone to persistent sub-surface deformation and fine scratches. Vibratory polishing uses extremely fine abrasives (often 0.05 μm colloidal silica) to gradually remove remaining scratches without introducing new ones.

4. When Preparing Delicate or Edge-Retaining Specimens

Extremely thin specimens, small parts, or samples with sensitive edges and coatings may deform under mechanical loads. Because the vibratory process is nearly load-free, it prevents edge rounding and preserves dimensional features.

This is especially useful for failure analysis in electronics, oxide or coating interface studies, and small cross-sectional samples.

5. When Preparing Large, Flat Surfaces

Mechanical polishers can introduce subtle waviness on larger samples due to platen dynamics and operator pressure variations. Vibratory polishing produces an exceptionally flat surface regardless of specimen size.

Applications include:

- Metallographic coupons for aerospace alloys

- Heat-treated steel plate sections

- Large embedded mounts used for quality control labs

Advantages Over Other Final Polishing Techniques

Compared to High-Speed Mechanical Polishing

- No risk of introducing new deformation

- No rotational drag or pullout of fragile phases

- More consistent surface across large samples

Compared to Chemomechanical Polishing

- Reduced risk of chemical attack or staining

- Less sensitivity to slurry chemistry

- No need for specialized pads or corrosive agents

Compared to Short-Duration Colloidal Silica Polishing

- Longer process time but dramatically better final finish

- Superior flatness and scratch removal

- Less chance of overpolishing or relief formation

Best Practices for Vibratory Polishing

Although vibratory polishing is forgiving, optimal results depend on controlling key variables.

Use the Right Slurry

The most common choice is 0.05 μm colloidal silica, which provides both mechanical and chemical polishing action. For harder materials, alumina suspensions (0.02–0.3 μm) can be used as needed.

Maintain Proper Specimen Loading

Specimens should be placed so they are evenly distributed and not touching each other. Overloading the bowl reduces vibratory efficiency and increases cycle time.

Control Fluid Levels

Too much slurry can reduce vibrational energy transfer; too little can cause drying or contamination. The slurry should form a thin, uniform film over the polishing cloth.

Use Appropriate Polishing Cloths

Soft, napped, or flocked cloths (such as Microcloth, VerduTex, or similar) are typical. Cloth selection depends on material hardness and desired finish.

Time Management

Most vibratory polishing cycles run from 30 minutes to 2 hours, but extremely demanding applications may require longer. Evaluate progress regularly to avoid overpolishing.

Common Mistakes to Avoid

- Skipping intermediate polishing steps – Vibratory polishing cannot correct severe scratches or subsurface damage.

- Allowing slurry to thicken or dry out – Leads to uneven removal or contamination.

- Using excessive specimen load – Reduces vibrational amplitude and efficiency.

- Failing to clean specimens between steps – Cross-contamination can create new scratches.

Safety Considerations

Although vibratory polishers operate quietly and with minimal operator intervention, standard safety practices apply:

- Wear gloves and eye protection when handling polishing suspensions.

- Ensure equipment is stable and level to prevent movement during long cycles.

- Clean spills immediately to avoid slips and contamination.

Conclusion

Vibratory polishing is a highly effective technique that excels when the highest-quality surface finish is required. It is particularly advantageous for EBSD applications, multiphase materials, delicate samples, and large or flat specimens. While cycle times are longer than those of high-speed polishing methods, the resulting surface is often superior—flatter, cleaner, and virtually free of deformation.

For metallographers seeking reliable, repeatable, and exceptionally high-quality results, vibratory polishing remains an essential tool in the sample preparation arsenal.

Want to Learn More?

Explore our comprehensive guides for detailed step-by-step instructions on sample preparation techniques.

Browse GuidesRelated Posts

The Role of Surface Flatness in Accurate Metallographic Evaluation

Learn why surface flatness is critical for accurate metallographic evaluation and how preparation decisions influence flatness and measurement accuracy.

Read More

Understanding Overpolishing and How to Identify It in Metallographic Samples

Learn how to identify overpolishing in metallographic samples and why it affects microstructural accuracy and surface integrity.

Read More

Welcome to the Metallography.org Blog

We're excited to launch our blog dedicated to metallographic sample preparation, analysis techniques, and industry insights. Join us as we share expert knowledge, practical tips, and real-world case studies.

Read More