Tool Steel and Hardened Steel Sample Preparation

A comprehensive guide to preparing very hard tool steels and hardened steels for metallographic analysis, with emphasis on preserving carbides and revealing complex microstructures.

Introduction

Tool steels and hardened steels are among the most challenging materials to prepare for metallographic analysis. These materials are very hard (typically 200-450 HB, 20-50 HRC) and contain complex carbide structures that must be preserved throughout preparation. The high hardness requires extended grinding and polishing times, while the presence of carbides demands careful techniques to avoid pullout or damage.

Critical Principle: Carbide preservation is essential. Carbides are hard, brittle phases that can be pulled out during grinding and polishing, leaving voids in the microstructure. Extended preparation times and careful monitoring are required.

1095 Steel water quenched to martensite, Vilella's reagent, 1000X magnification. Tool steels and hardened steels typically show martensitic structures with carbides. Proper preparation preserves carbides while revealing the matrix microstructure.

This guide covers several categories of very hard materials:

- Tool Steels: Air-hardening (A2, A4, A6), oil-hardening (O1), high-speed steels (M2, M42), hot-work (H11, H13, H21), and cold-work (D2) tool steels

- Through-Hardened Steels: Steels like 1080, 52100, and 4340 in their hardened condition

- Case-Hardened Steels: Carburized or nitrided steels like 8620 and 9310 with hardened surface layers

All of these materials share common preparation challenges: very high hardness, presence of carbides, and the need for extended preparation times. The techniques described here apply to all of them, with specific notes for particular material types.

Sectioning

When sectioning tool steels and hardened steels, use slow cutting speeds to minimize heat generation and prevent phase transformation. These materials are very hard and generate significant heat during cutting. Use appropriate blades designed for hard materials.

MAX-VHS abrasive cut-off blades designed for very hard and case-hardened steels. These blades are essential for tool steels and hardened steels.

- Use MAX-VHS series blades designed for very hard materials

- Use slow cutting speeds (80-150 RPM) to minimize heat generation

- Use a thin abrasive cut-off wheel (0.5-1.0 mm thickness)

- Apply steady, moderate pressure - avoid forcing

- Use adequate coolant to prevent overheating and phase transformation

- Allow the wheel to do the cutting - these materials are very hard

Important: For case-hardened steels, cut perpendicular to the case to preserve the case-core interface. For through-hardened steels, standard cutting techniques apply, but use slower speeds due to high hardness.

Example Products: MAX-VHS Abrasive BladesMAX-VHS blades specifically designed for very hard and case-hardened steels

For purchasing options and product specifications, see commercial supplier website.

Mounting

Mounting provides edge retention and easier handling. For tool steels and hardened steels, compression mounting with phenolic resin is strongly recommended for better edge retention, especially for case-hardened steels where the case-core interface must be preserved.

Compression Mounting

Phenolic resin provides excellent edge retention, which is critical for case-hardened steels and for preserving carbide structures near edges.

- Clean the sample thoroughly to remove cutting fluid and debris

- Place sample in mounting press with phenolic resin (preferred) or epoxy

- Apply pressure: 3000-4000 psi for phenolic, 2000-3000 psi for epoxy

- Heat to 150-180°C and hold for 5-8 minutes

- Cool under pressure to room temperature

For Case-Hardened Steels: Mount with the case edge exposed if you need to analyze the case depth. Ensure proper edge retention to preserve the case-core interface.

Example Products: Compression Mounting EquipmentAutomatic and manual mounting presses for consistent results

For purchasing options and product specifications, see commercial supplier website.

Grinding

Grinding removes sectioning damage and prepares the surface for polishing. For tool steels and hardened steels, use extended grinding sequences with longer times per step due to the very high hardness. The presence of carbides requires careful technique to avoid pullout.

Important: These materials are very hard and require extended grinding times. Expect 60-120 seconds per grit, significantly longer than softer materials. Carbides can be pulled out if grinding is too aggressive - use consistent, moderate pressure.

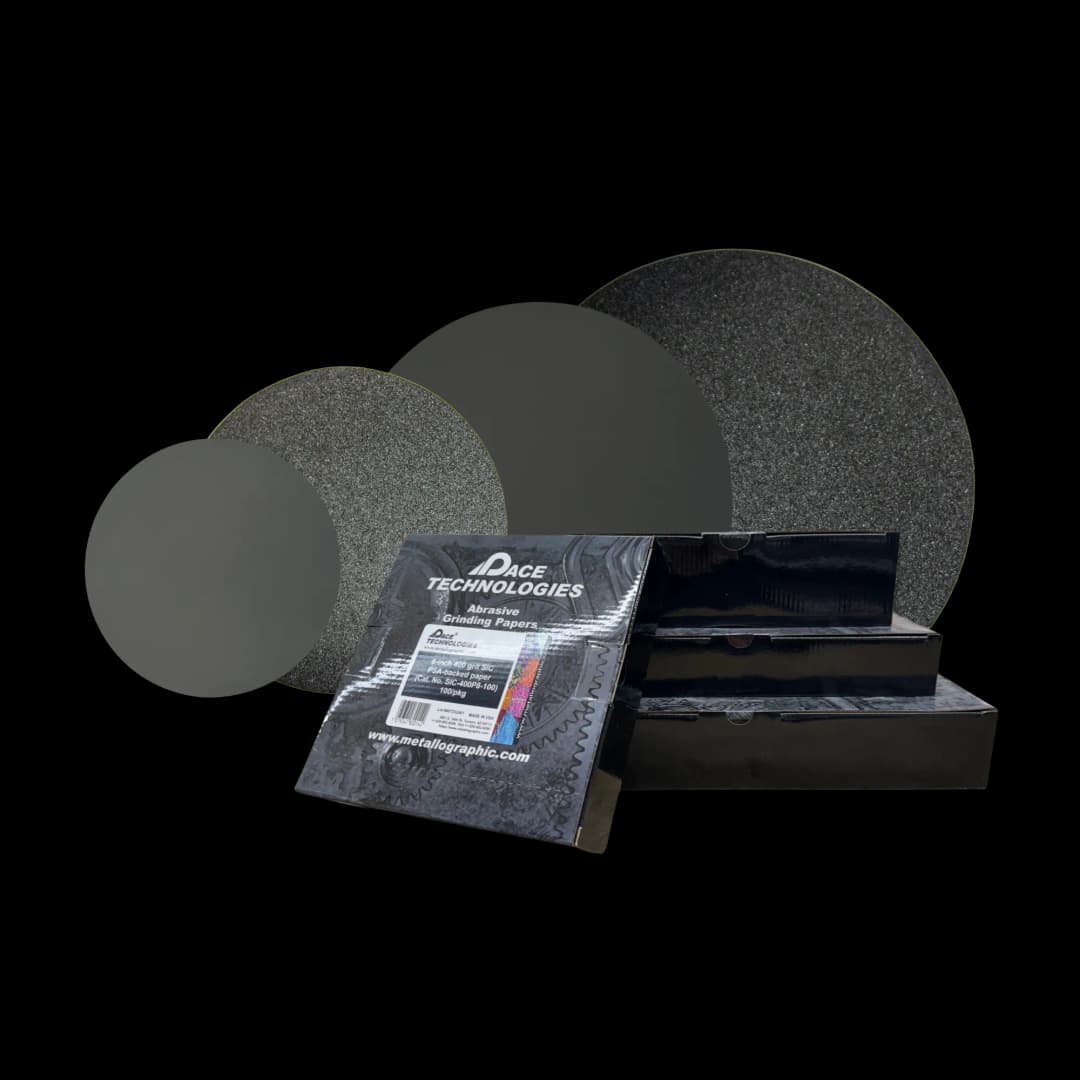

Silicon carbide (SiC) grinding papers in various grit sizes (120, 240, 400, 600, 800, 1200) for progressive grinding. Extended sequences and longer times are required for very hard tool steels.

Grinding Sequence

For tool steels and hardened steels, use an extended grinding sequence:

- 120 grit: Remove sectioning damage (60-120 seconds per step, moderate pressure)

- 240 grit: Remove previous scratches (60-120 seconds, moderate pressure)

- 320 grit: Further refinement (60-120 seconds, moderate pressure)

- 400 grit: Additional refinement (60-120 seconds, moderate pressure)

- 600 grit: Final grinding step (60-120 seconds, moderate pressure)

- 800 grit (optional): For high-quality work (60-120 seconds, moderate pressure)

- 1200 grit (optional): For very high-quality work (60-120 seconds, moderate pressure)

Critical Guidelines:

- Use extended times (60-120 seconds per grit) - these materials are very hard

- Use consistent, moderate pressure - avoid excessive pressure that could pull out carbides

- Rotate the sample 90° between each grit to ensure complete removal of previous scratches

- Use water as a lubricant and maintain consistent pressure

- Monitor the surface - if carbides start to pull out, reduce pressure slightly

- For case-hardened steels, be especially careful near the case-core interface

Note: The optional 800 and 1200 grit steps are recommended for high-quality work, especially for carbide-rich materials like high-speed steels (M2, M42) and D2 tool steel.

Example Products: Silicon Carbide Grinding Papersappropriate SiC papers in all grit sizes for consistent grinding

For purchasing options and product specifications, see commercial supplier website.

Polishing

Polishing removes grinding scratches and prepares a mirror-like surface. For tool steels and hardened steels, use extended polishing sequences with longer times per step due to the very high hardness. Carbide preservation is critical - use appropriate cloths and techniques to avoid pullout.

Key Principle: Carbides are hard, brittle phases that can be pulled out during polishing, leaving voids in the microstructure. Use appropriate cloth hardness and extended times to preserve carbides while achieving a good surface finish.

Diamond Polishing

Use an extended diamond polishing sequence with longer times:

- 9 μm diamond: 5-8 minutes on a hard cloth (e.g., Texmet), moderate pressure

- 6 μm diamond: 5-8 minutes on a medium-hard cloth, moderate pressure

- 3 μm diamond: 5-8 minutes on a medium-hard cloth, moderate pressure

- 1 μm diamond: 3-5 minutes on a soft cloth, lighter pressure

Final Polishing

- 0.05 μm colloidal silica: 2-3 minutes on a soft cloth, light pressure

- Rinse thoroughly with water and dry with compressed air

Critical Guidelines:

- Use extended times (5-8 minutes per diamond step) - these materials are very hard

- Use appropriate cloth hardness - harder cloths for coarser steps, softer for fine steps

- Use moderate pressure for diamond steps, lighter for final polishing

- Monitor the surface - carbides should remain intact, not pulled out

- Avoid over-polishing - extended times can cause relief around carbides

- For case-hardened steels, be especially careful near the case-core interface

For High-Speed Steels (M2, M42): These contain complex carbides (M₆C, MC, M₂C) that are particularly prone to pullout. Use softer cloths and lighter pressure, especially in the final steps.

For Case-Hardened Steels: The case layer is very hard and may require even longer polishing times. Be careful to preserve the case-core interface.

Example Products: Diamond Abrasivessuitable diamond polishing compounds in various particle sizes

For purchasing options and product specifications, see commercial supplier website.

Example Products: Polishing Padsappropriate polishing pads for different polishing stages

For purchasing options and product specifications, see commercial supplier website.

Etching

Etching reveals the microstructure by selectively attacking grain boundaries and phases. For tool steels and hardened steels, the choice of etchant depends on the material type, heat treatment, and what features you want to reveal. Nital and Vilella's Reagent are the most common etchants.

Tool steel microstructure after proper etching. The matrix structure and carbides are revealed by appropriate etching.

Common Etchants for Tool Steels and Hardened Steels

- 2% Nital: General purpose for most tool steels and hardened steels. Reveals martensite structure and grain boundaries (2% HNO₃ in ethanol)

- 3-5% Nital: For very hard materials, higher concentrations may be needed (3-5% HNO₃ in ethanol)

- Vilella's Reagent: Excellent for revealing carbides and martensite structure. Particularly useful for high-speed steels and tool steels with complex carbides (1g picric acid, 5ml HCl, 100ml ethanol)

- Picral: Useful for revealing cementite and pearlite structures in some tool steels (2-4g picric acid per 100ml ethanol)

- Murakami's Reagent: For revealing carbides in high-speed steels and tool steels (10g K₃Fe(CN)₆, 10g KOH, 100ml H₂O)

Etching solutions and reagents for tool steels and hardened steels. Common etchants include Nital, Vilella's Reagent, and Murakami's Reagent.

Etching Procedure

- Ensure sample is clean and dry after polishing

- Apply etchant with cotton swab or immerse sample

- Etch for 10-30 seconds (time varies by material type and hardness)

- Immediately rinse with water, then alcohol

- Dry with compressed air

Important Notes:

- Start with shorter etching times (10-15 seconds) and increase if needed

- For very hard materials, longer etching times (20-30 seconds) may be needed

- Vilella's Reagent is particularly useful for tool steels and high-speed steels with complex carbides

- Murakami's Reagent is excellent for revealing carbides in high-speed steels (M2, M42)

- For case-hardened steels, etching reveals the case microstructure and case depth

- Over-etching can obscure fine details - start with shorter times

For High-Speed Steels (M2, M42): These contain complex carbides that may require specialized etchants like Murakami's Reagent to reveal properly. Vilella's Reagent is also effective.

For Case-Hardened Steels: Etching reveals the case microstructure and allows measurement of case depth. Use appropriate etchants to reveal the case-core interface clearly.

Example Products: EtchantsPre-mixed and custom etching solutions for tool steels, including Nital, Vilella's Reagent, and Murakami's Reagent

For purchasing options and product specifications, see commercial supplier website.

Troubleshooting

Common Issues and Solutions

- Carbide pullout: Too much pressure during grinding or polishing, or inappropriate cloth hardness. Reduce pressure, use softer cloths for fine steps, and monitor the surface carefully. Carbides are hard and brittle and can be pulled out easily.

- Scratches remaining: Insufficient grinding/polishing time. These materials are very hard and require extended times (60-120 seconds per grit, 5-8 minutes per polishing step). Ensure complete scratch removal at each step.

- Relief around carbides: Over-polishing or too soft a cloth. Reduce polishing time or use slightly harder cloth, but still maintain moderate pressure to avoid carbide pullout.

- Contamination: Clean between steps, use fresh abrasives, and ensure proper sample cleaning.

- Poor edge retention: Consider using phenolic mounting material or different mounting technique. For case-hardened steels, edge retention is critical for case depth measurement.

- Over-etching: Reduce etching time or use lower etchant concentration. Start with shorter times (10-15 seconds).

- Under-etching: Increase etching time or use higher etchant concentration. These materials are very hard and may require longer etching times (20-30 seconds).

- Phase transformation during cutting: Use slower cutting speed and adequate coolant to prevent overheating. These materials are sensitive to heat.

- Case-core interface not visible: For case-hardened steels, ensure proper mounting with edge exposed, use appropriate etching, and preserve edge retention throughout preparation.

Remember: Tool steels and hardened steels are very hard and require extended preparation times. The most common mistakes are insufficient time per step and excessive pressure that causes carbide pullout. Always err on the side of longer times and careful monitoring.

Explore More Procedures

Browse our comprehensive procedure guides for material-specific preparation methods and get personalized recommendations.